Who We Are

Lets Work Together

Trust in the Potential of Aluminum – We Know What It Can Achieve.

For over a decade, BGA Aluminum has been a leader in providing high-quality, precision pretreated aluminum solutions. We specialize in developing advanced anodizing technologies that meet the most stringent industrial demands. Our collaborative approach and commitment to innovation allow us to bring your vision to life, delivering top-tier aluminum products tailored to your specifications.

With state-of-the-art facilities in Guangdong, China, and a team of experts driving innovation, BGA Aluminum is at the forefront of the aluminum industry. Our commitment to continuous technological advancement and customer satisfaction makes us the trusted partner for industries like construction, automotive, electronics, and more.

Our Mission

At BGA, we are committed to being the preferred partner in aluminum solutions for industries worldwide. We focus on providing precision products that consistently meet the highest standards, ensuring quality and reliability every time. Our mission is to drive innovation, exceed customer expectations, and continue to lead the aluminum industry through continuous improvement and technological advancements.

Innovative, Durable, and Functional Aluminum Solutions

Pioneering the Future of Anodizing and Surface Treatment Technology

The Story of BGA

Founded with a focus on delivering high-quality aluminum products, BGA Aluminum has continuously evolved to meet the demands of modern industries. Our story is one of passion, dedication, and a commitment to excellence. From our pioneering developments in anodizing technology to becoming a leader in precision pretreated aluminum, BGA continues to shape the future of the aluminum industry.

2013 | Revolutionizing LED Substrates

Developed electrostatic adsorption composite technology for anodized aluminum sheets, launching the L-Series LED Substrates. These products eliminated critical flaws in traditional solutions—delamination, inconsistent adhesion, and color variation—delivering unmatched stability for high-precision applications.

2014 | Efficiency Redefined

Pioneered non-contact, continuous horizontal anodizing systems, boosting client material efficiency by 40%+ while ensuring batch-to-batch consistency. A game-changer for cost-sensitive industries demanding zero compromise on quality.

2015 | The AES Breakthrough

Introduced AR-Series with Advanced Electrolytic Surface (AES) Technology—achieving the industry’s thinnest corrosion-resistant film (≤3μm) without sacrificing durability. A dual-purpose marvel combining sleek aesthetics with industrial-grade performance.

2018 | Ultra-Thin Revolution

Mastered 0.18mm coil anodizing & electrophoretic coating—a first in ultra-thin processing. This innovation set global benchmarks for precision circuit boards and luxury decorative composites, slashing material waste by 22%.

2020 | The Steel Structure Savior

Unveiled Composite Porcelain Electrophoresis Technology for aluminum roofing/wall panels. Engineered for steel buildings, it delivers:

- 30+ years rust-free lifespan

- 96% recyclability (vs. 60% industry average)

- Chemical-proof performance

Now the gold standard for chemical plants and advanced manufacturing campuses.

2022 | Pushing Thinner, Smarter

Broke barriers with 0.03mm anodized aluminum foil—thinner than a human hair—enabling next-gen compact circuits for EVs, solar tech, and IoT devices.

2023 | Scaling New Dimensions

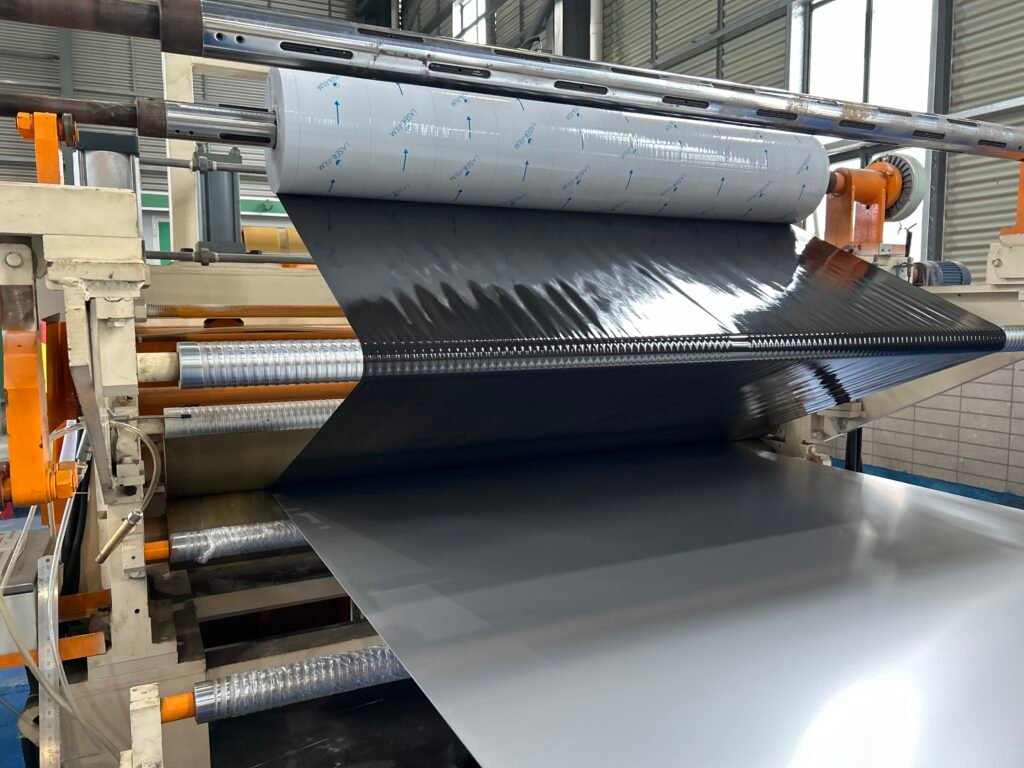

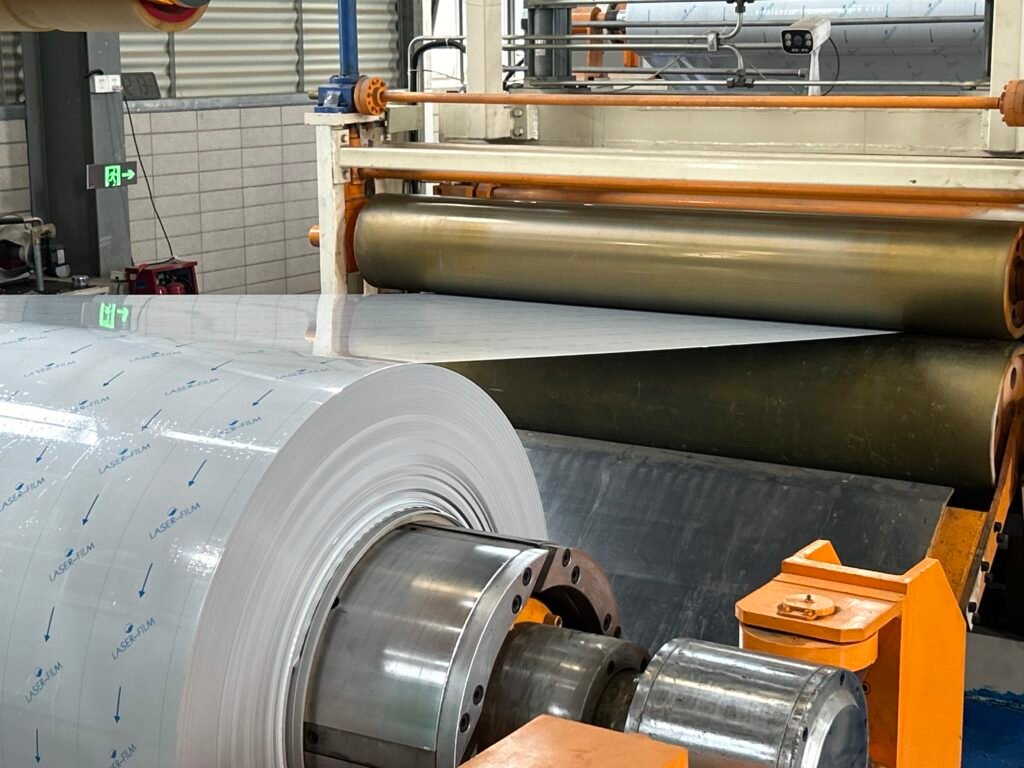

Launched Jumbo-Sized Coil-to-Coil Lines capable of processing 2,500mm-wide, 5mm-thick substrates—perfect for mega architectural projects requiring seamless oxidized surfaces.

2024 | Beyond Boundaries

Our R&D pipeline includes:

- AI-driven anodizing quality control systems

- Zero-waste closed-loop production

- Self-healing nano-coatings

The future of aluminum starts here.